© TUB F1

© TUB F1

Aktuelles

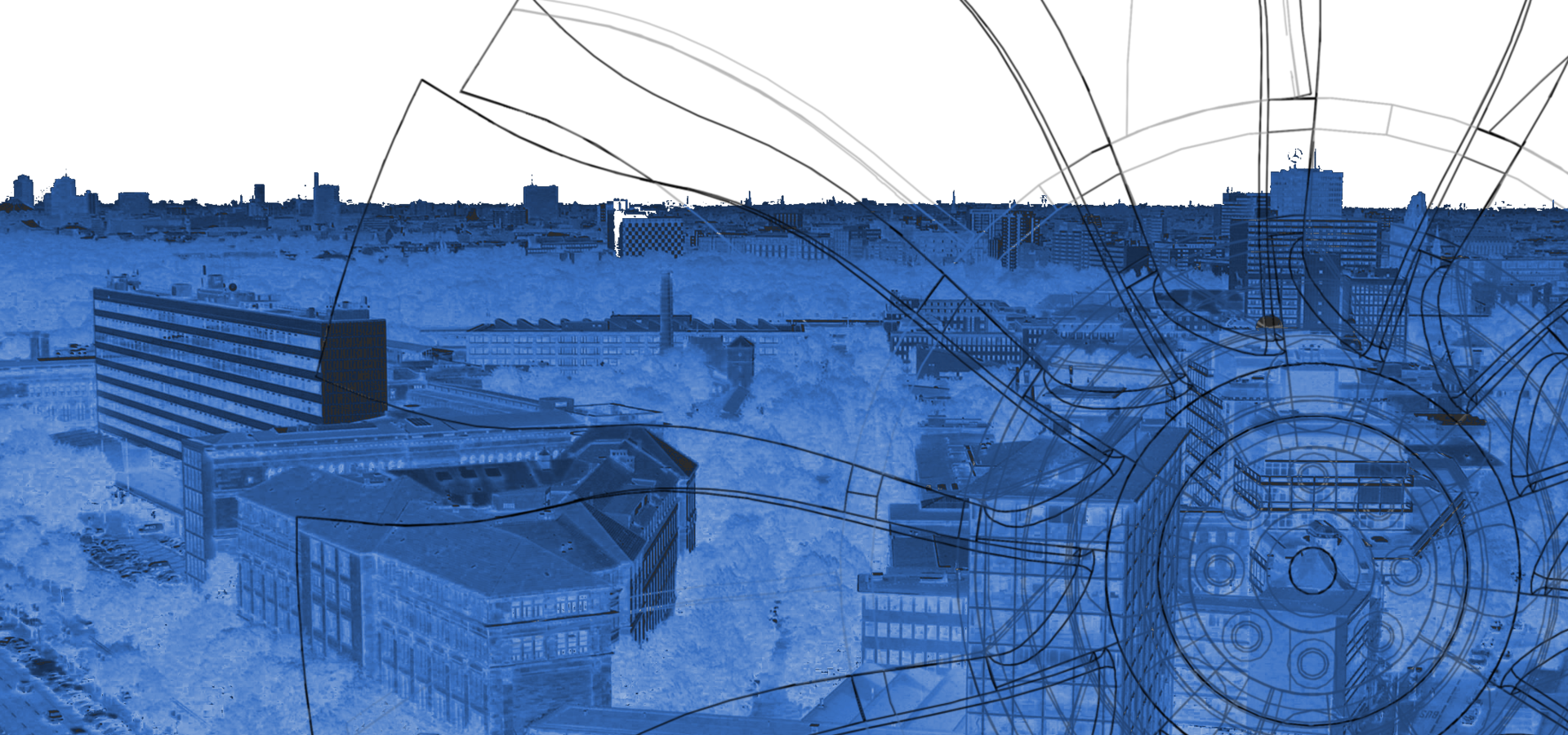

Fachgebiet Luftfahrtantriebe

Das Fachgebiet Luftfahrtantriebe deckt alle Arten luftatmender Strahlantriebe sowie der thermischen Strömungsmaschinen ab. Funktionssicherheit, Wirtschaftlichkeit und Umweltverträglichkeit sind die globalen Ziele der modernen Turbomaschinenentwicklung. Dazu ist die genaue Kenntnis der relevanten strömungsmechanischen, wärmetechnischen und konstruktiven Möglichkeiten und Methoden erforderlich.

Ziel ist die anwendungsorientierte Weiterentwicklung und Optimierung der Strömungsmaschinen unter Berücksichtigung der Konstruktion, der Sekundärsysteme, der Verbrennung und der Schadstoff- und Lärmentstehung. Dies schließt ebenso das Betriebsverhalten des Gesamtsystems Luftfahrtantrieb im gesamten Einsatzbereich sowie Zuverlässigkeits- und Sicherheitsaspekte ein. Einen größeren Umfang stellen hierbei die thermischen Strömungsmaschinen dar, die den gesamten industriellen Einsatzbereich von Verdichtern und Turbinen abdecken. Die Auslegung der Maschine inklusive der Schaufelprofilierung zur Erfüllung der strömungsmechanischen Anforderungen stehen hier im Mittelpunkt, wobei wichtige Mechanismen des Wärmeübergangs und der Bauteilkühlung ebenfalls in die Auslegung einfließen müssen.

Informationen zum Fachgebiet und zu unserer Forschung findet man in der Broschüre CHAIR OF AERO ENGINES

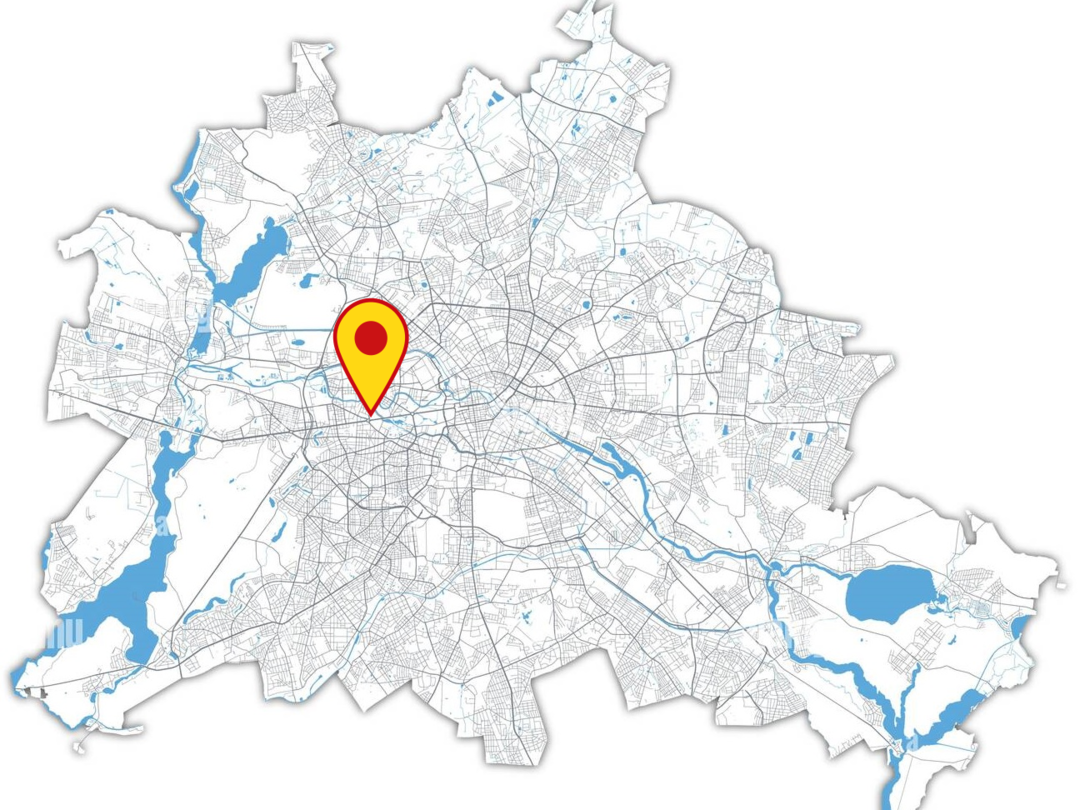

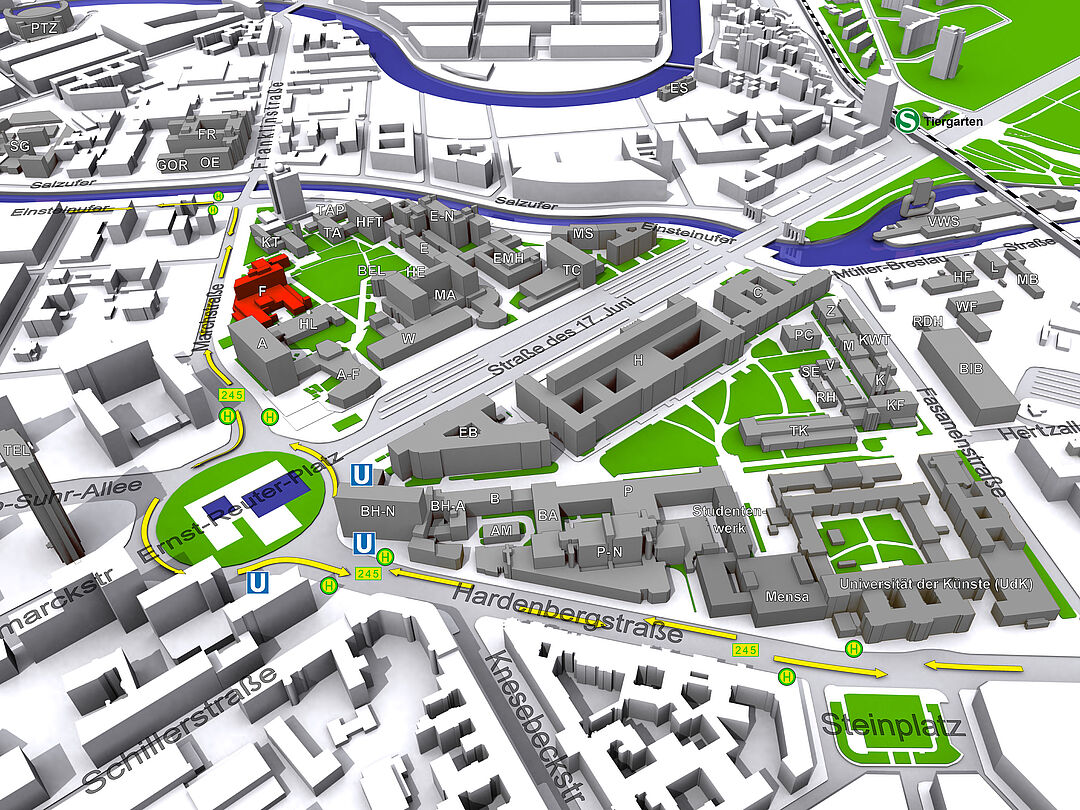

Wo Sie uns finden

© Sabine Böck

© Sabine Böck

© TUB F1

© TUB F1